CASE STUDIES

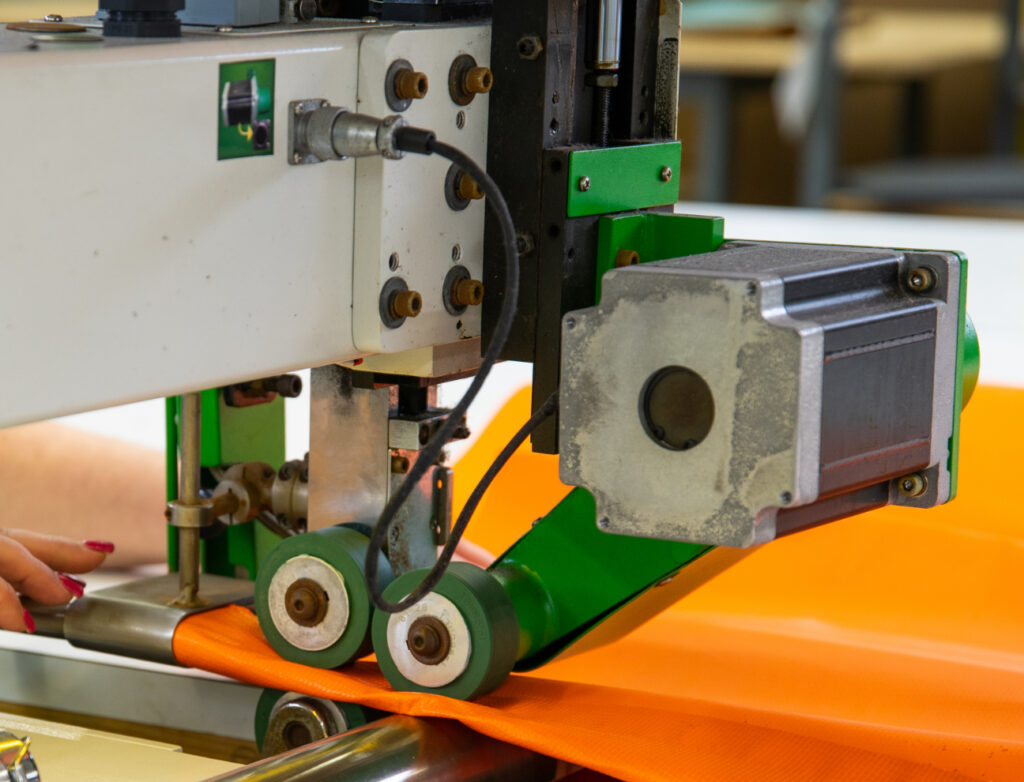

ABOUT FAIRWAY PRODUCTS

We are an ISO 9001:2008 certified facility. This plant is a 3-shift operation that provides a broad range of products and services to the automotive, office furniture, and general industrial markets. Fairway’s modern cut, sew and assemble capabilities, combined with the synergy we have developed with our sister divisions – gives us the quality oriented, cost efficient background to manufacture components, sub-assemblies and finished products to the specifications required by our customers.